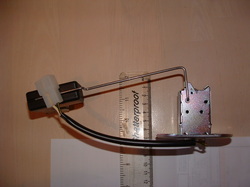

Fuel Level Sender Unit

We have obtained a limited stock of new replacement fuel sender units for the Z1-R models.

They come complete with a new gasket for the tank joint.

A new cover with drip tube joint is also included.

A new cover with drip tube joint is also included.

Here is the outer view of the cover.

It also has an exit point for the sender unit wiring.

It also has an exit point for the sender unit wiring.

As you can see the factory cover was a lot shallower and the two covers cannot be swapped between new and original sender units.

The original cover is more flexible and rubbery to the touch.

The new cover is made of a harder plastic material.

The original cover is more flexible and rubbery to the touch.

The new cover is made of a harder plastic material.

When fitting the new unit ensure that there is a clean joint surface on the tank side. The unit can be inserted if the float is fed inside first and then rotated 90 degrees after it is inside.

The new gasket is an exact match for the original factory part - which is no longer available.

These six shouldered bolts fit exactly into the base plate of the new unit.

Part code is 92001-1069 if you need the correct ones.

Part code is 92001-1069 if you need the correct ones.

The wiring faces out and must be turned to match the exit point on the cover.

There is an arrow to show which way should be facing forward on the base plate.

There is an arrow to show which way should be facing forward on the base plate.

The base plate of the sender is larger than the base plate on the tank.

This is correct - and provides a lip for the cover to grip onto when it is hanging under the tank after fitting.

This is correct - and provides a lip for the cover to grip onto when it is hanging under the tank after fitting.

The cover can be clicked into place once the cables are routed like this to allow an interior exit point.

The large tube at front can be connected to a vent tube which will allow any escaped drops of fuel to exit the engine area without hazard.

The large tube at front can be connected to a vent tube which will allow any escaped drops of fuel to exit the engine area without hazard.

Because the new cover is deeper than an original factory item it will protrude slightly below the base line of the tank. By about 5mm.

This should not be noticeable from above when fitted to the machine.

This should not be noticeable from above when fitted to the machine.

Here is another view of the cover, as you can see the overlap is only slight.

The connector block will join back onto the wiring harness later.

The connector block will join back onto the wiring harness later.

The sender unit itself does not protrude if the cover is left off.

As can be seen in this shot.

As can be seen in this shot.

The float height from the unit base is about 18cm when fully extended.

This would be the full tank position.

This would be the full tank position.

The float height from the unit base is about 5.5cm when at rest.

This would be the empty tank position.

At this point the right angle part of the float arm is actually the highest point at around 7cm above the unit base.

This would be the empty tank position.

At this point the right angle part of the float arm is actually the highest point at around 7cm above the unit base.

Here is the unit fully extended against a small 13 litre tank.

These had an offset gas cap and were only used on early D1 models from 1978 & 1979.

A taller tank was standard on all later models and supplied as an upgrade for early ones.

You may need to gently bend the float arm to adjust for clearance on your tank.

These had an offset gas cap and were only used on early D1 models from 1978 & 1979.

A taller tank was standard on all later models and supplied as an upgrade for early ones.

You may need to gently bend the float arm to adjust for clearance on your tank.

The correct block connection is supplied.

Here you can see the sender unit connected to a Z1-R wiring harness.

If you have a different connector your loom may have been altered and this unit will not be a straight fit.

Because this connection has to be parted every time the tank is removed for servicing it often got loose or damaged.

If you have a different connector your loom may have been altered and this unit will not be a straight fit.

Because this connection has to be parted every time the tank is removed for servicing it often got loose or damaged.